What Is Digital Transformation in Manufacturing?

The concept of digital transformation in the manufacturing industry refers to implementing digital technologies in all areas of a company's operations, including manufacturing, supply chain management, and customer service. It aims to increase efficiency, productivity, and flexibility while reducing costs and improving customer satisfaction.

What is the current state of digital transformation in manufacturing?

The manufacturing sector is currently experiencing rapid growth and a trend toward change. Many companies have already started to adopt digital technologies and strategies, while others are still in the early stages of their transformation.

- According to Gartner by 2022, 70% of customer engagements will be provided by intelligent systems.

- According to Gartner 91% of companies are involved in some digital initiative, and 87% of senior business leaders consider digitalization their priority.

- Businesses spent $58.3 billion on artificial intelligence in 2021, and that spending will increase to $309.6 billion by 2026, according to Markets and Markets

- According to PwC almost half of all companies say that improving customer experience and customer satisfaction was the main reason for embarking on a digital transformation.

- According to FinancesOnline 46% of small businesses use business intelligence tools.

- According to Precedence Research, the global Internet of Things (IoT) in the manufacturing market was valued at $202 billion in 2022 and is projected to reach approximately $1.169.76 trillion by 2030.

- Deloitte states that 93 percent of companies believe AI will be a pivotal technology to drive growth and innovation in manufacturing.

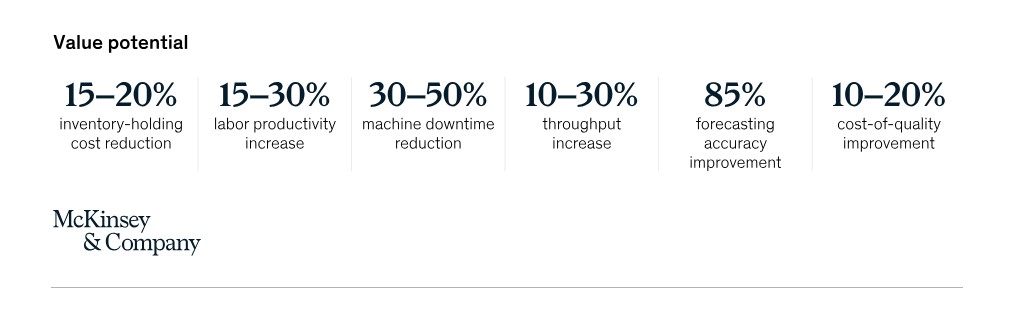

- McKinsey indicates that the digital transformation of a manufacturing company has the potential to:

- reduce inventory maintenance costs by 15-20%;

- increase labor productivity by 15-30%;

- reduce machine downtime by 30-50%;

- increase throughput by 10-30%;

- improve forecasting accuracy by 85%;

- improve cost-of-quality by 10-20%.

- Additive manufacturing, also known as 3D printing, uses digital models to create physical products layer by layer. It is useful for prototyping and custom products, allowing for more complex designs and faster production times.

- Robotics and automation are becoming more common in manufacturing, especially in tasks such as assembly and packaging. These technologies perform repetitive tasks faster and more accurately than workers while improving efficiency and reducing the risk of error.

- ERP systems are integrated with other digital tools, such as IoT sensors and analytics platforms, to provide better visibility and control of production processes. Cloud-based business resource management systems are also becoming more common, providing companies with greater flexibility and scalability.

- Augmented reality is used in production to provide workers with real-time information about the products they are working with. It can give workers step-by-step instructions, highlight potential problems, and guide them through complex processes.

- Digital twins are virtual models of physical products or processes used to simulate performance and optimize them before physical prototypes are created.

- Finally, supply chain management is also affected by digital transformation as companies adopt technologies such as blockchain and IoT sensors. IoT sensors can be used to monitor inventory levels and track shipments, while blockchain technology can provide greater transparency and security in supply chain transactions.

- The use of digital technologies in manufacturing, such as sensors, machines, and production processes, generates an ever-increasing amount of data. Therefore, big data analytics has become an essential aspect of the digitization of production. Manufacturers can use predictive data analytics to forecast maintenance needs and reduce downtime by predicting when equipment will need repairs. They can also use real-time data analytics to monitor the quality of manufactured products, identify any issues as they arise, and make adjustments accordingly. By analyzing customer data, manufacturers can identify trends and preferences, allowing them to tailor their products and services to meet customers' specific needs. In addition, big data analytics can also help manufacturers in their decision-making processes by making data-driven decisions rather than relying on gut feelings or assumptions.

Conclusion

Digital transformation is necessary to stay competitive in today's fast-paced business environment. With the right approach and support, manufacturers can unlock new opportunities for efficiency, productivity, and innovation.

As an experienced business digitalization company, we can help detect and implement the most appropriate technologies for your unique needs. In addition, we provide training and support to employees to ensure they can adapt to new digital tools and processes and fully realize the benefits of digital transformation.

Transform your manufacturing business today and use the full potential of digitalization. Contact us now!