If you are a manufacturer using Odoo, a popular and powerful enterprise resource planning (ERP) software, you may have encountered the need to create a multi-level Bill of Materials (BoM) for your manufactured products. A multi-level BoM allows you to define the hierarchical structure of components and sub-assemblies required to produce a finished product. In this article, we will guide you through the process of creating a multi-level BoM in system Odoo, step-by-step.

Step 1: Define Your Product Structure

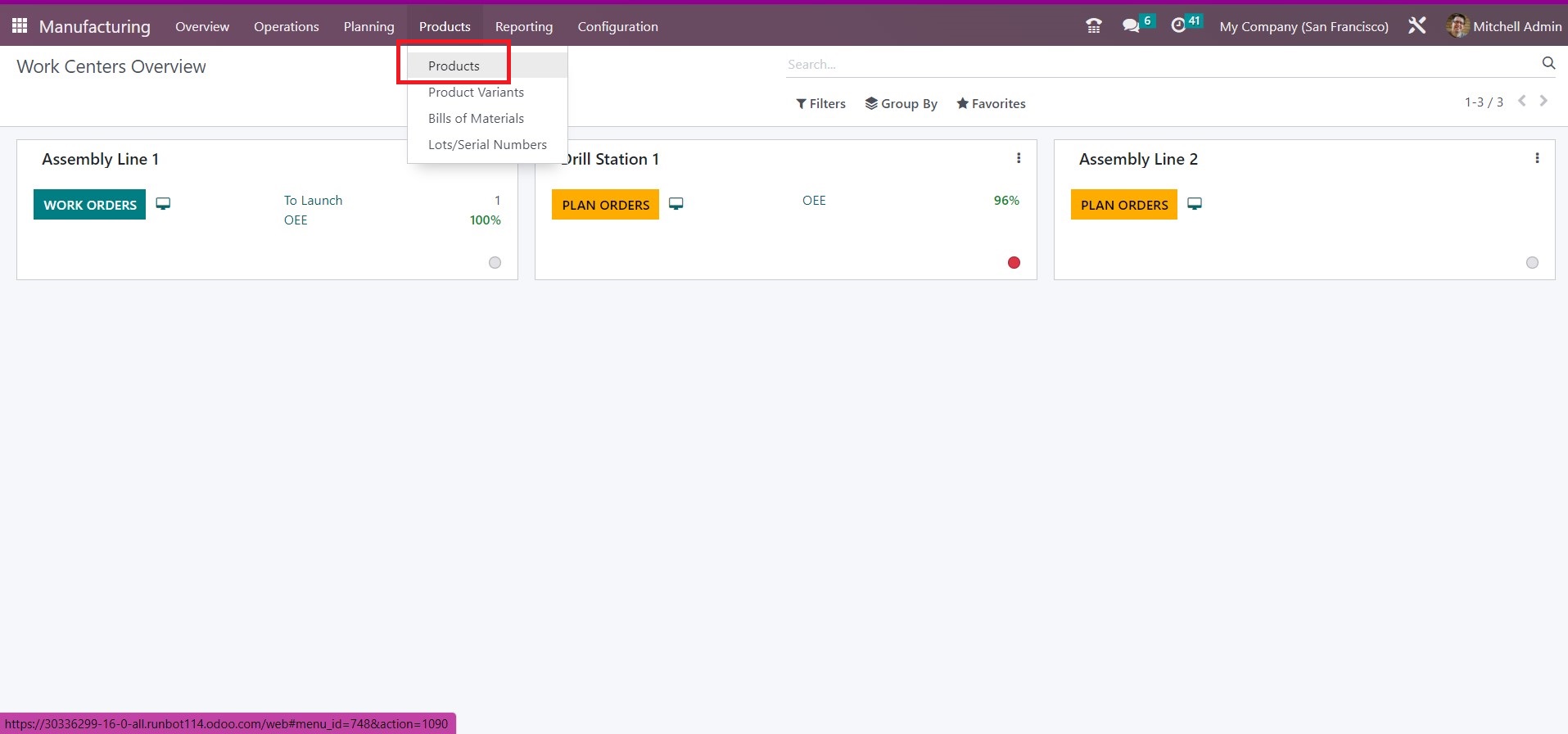

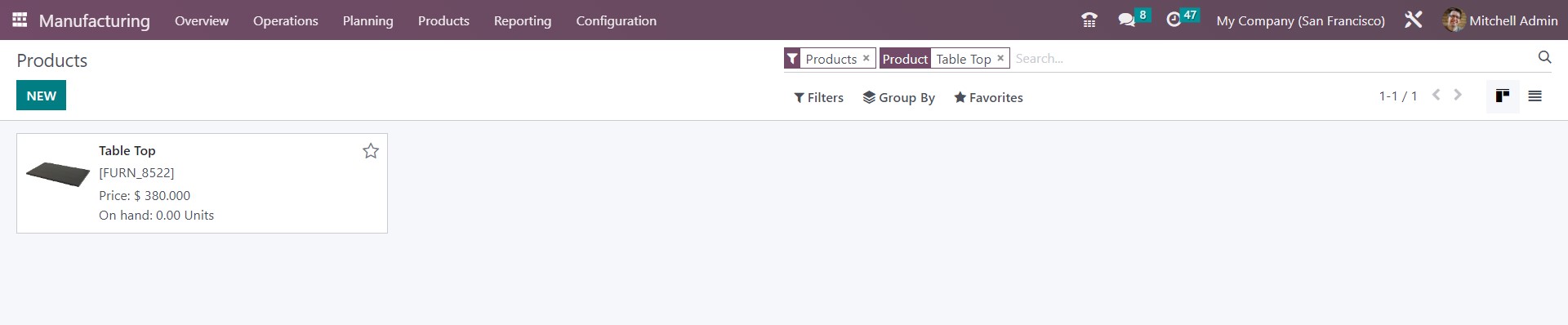

Before you start creating a multi-level BoM, you need to have a clear understanding of your product structure. This includes identifying all the components, sub-assemblies, and finished products that are part of your manufacturing process. You can create a product for each component or sub-assembly in Odoo using the "Products" section.

Here you can see all available raw materials.

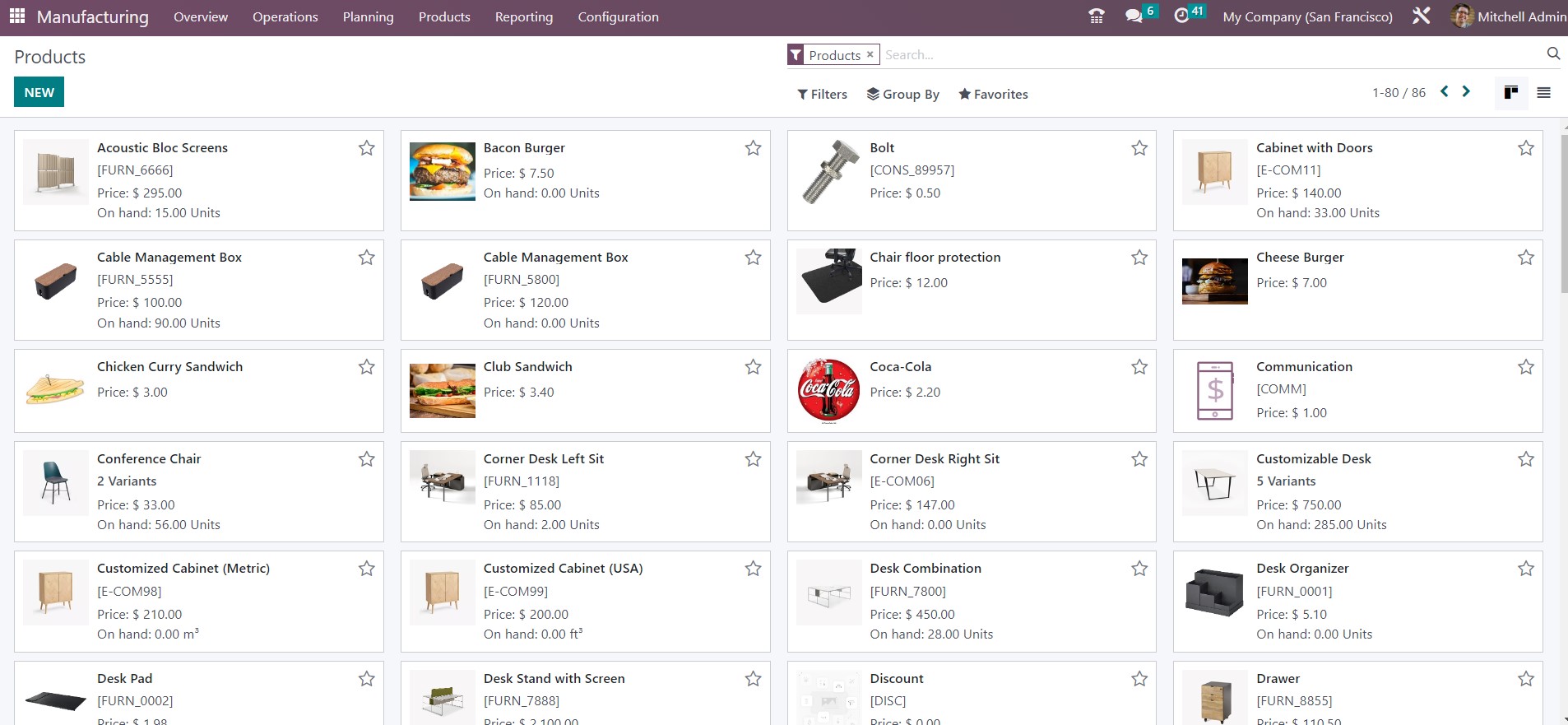

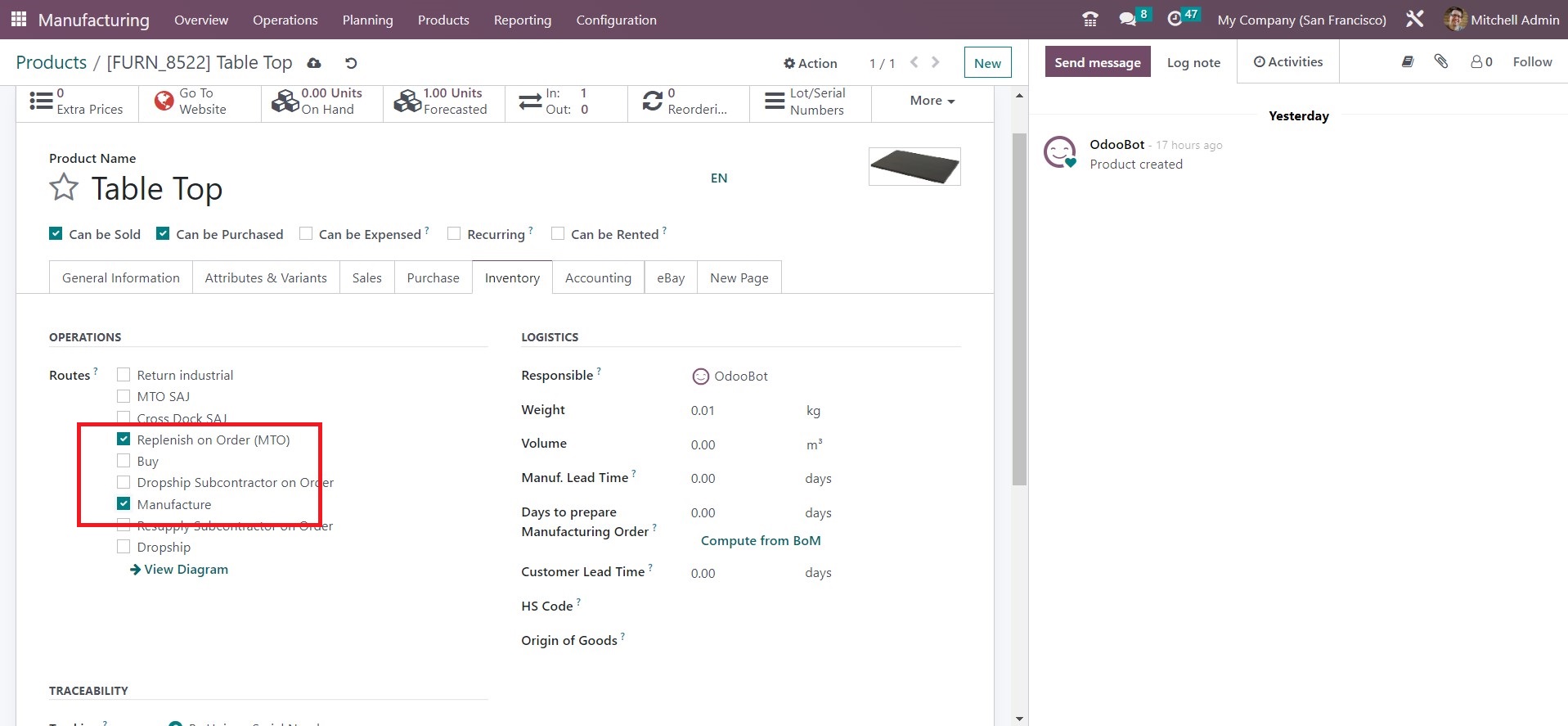

While creating the raw materials, you have to define the routes for these products. In this case, our Large Meeting Table BoM will consist of Office Chairs, Bolts, Screws, Table legs, and Table Top. For the Office Chairs, Bolts, Screws, and Table legs, we need to select routes MTO and Buy under the Inventory Tab so that in case the product is not currently in stock, the system will automatically generate the Request for Quotation to buy it.

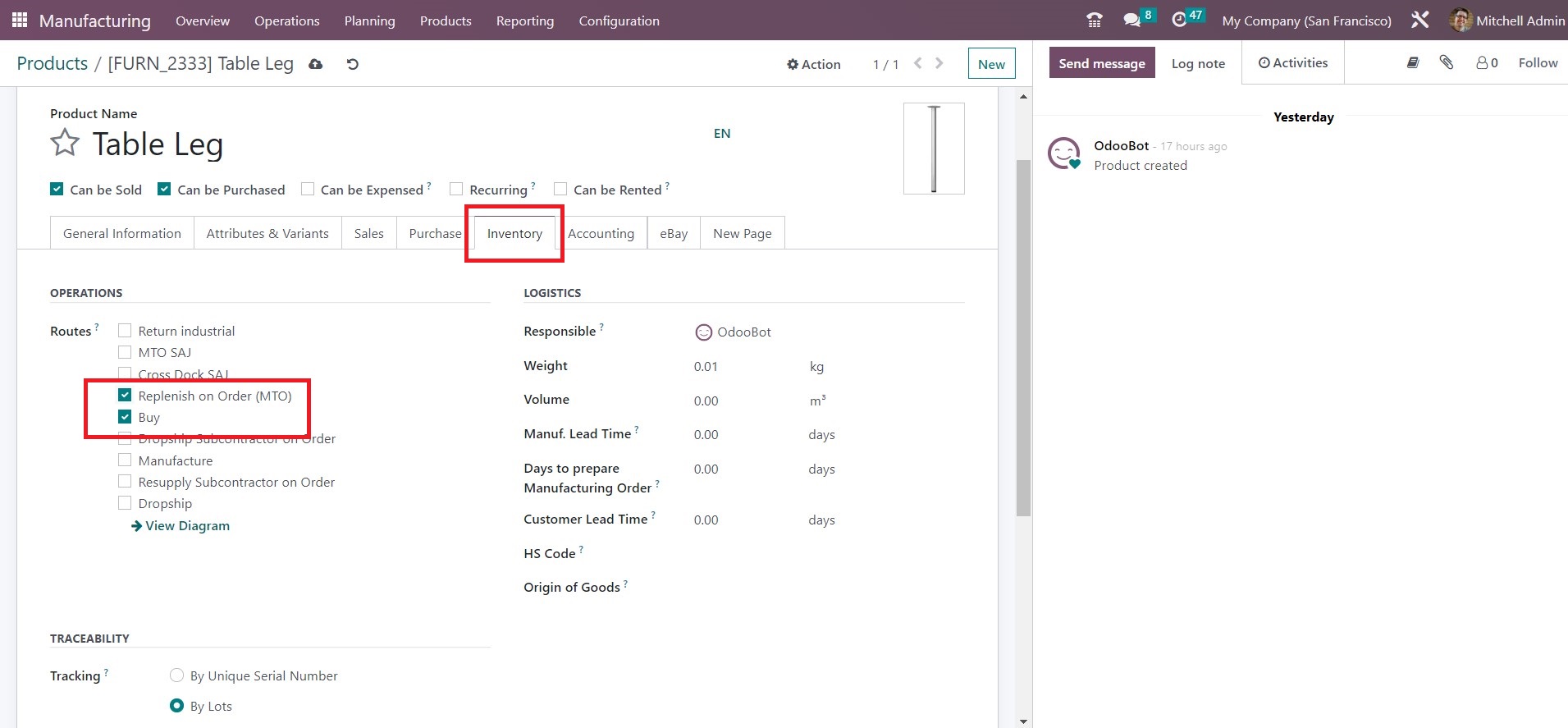

We will manufacture the Table Top ourselves. In this case, we have to check MTO and Manufacture so that the system will automatically create a draft Manufacturing Order.

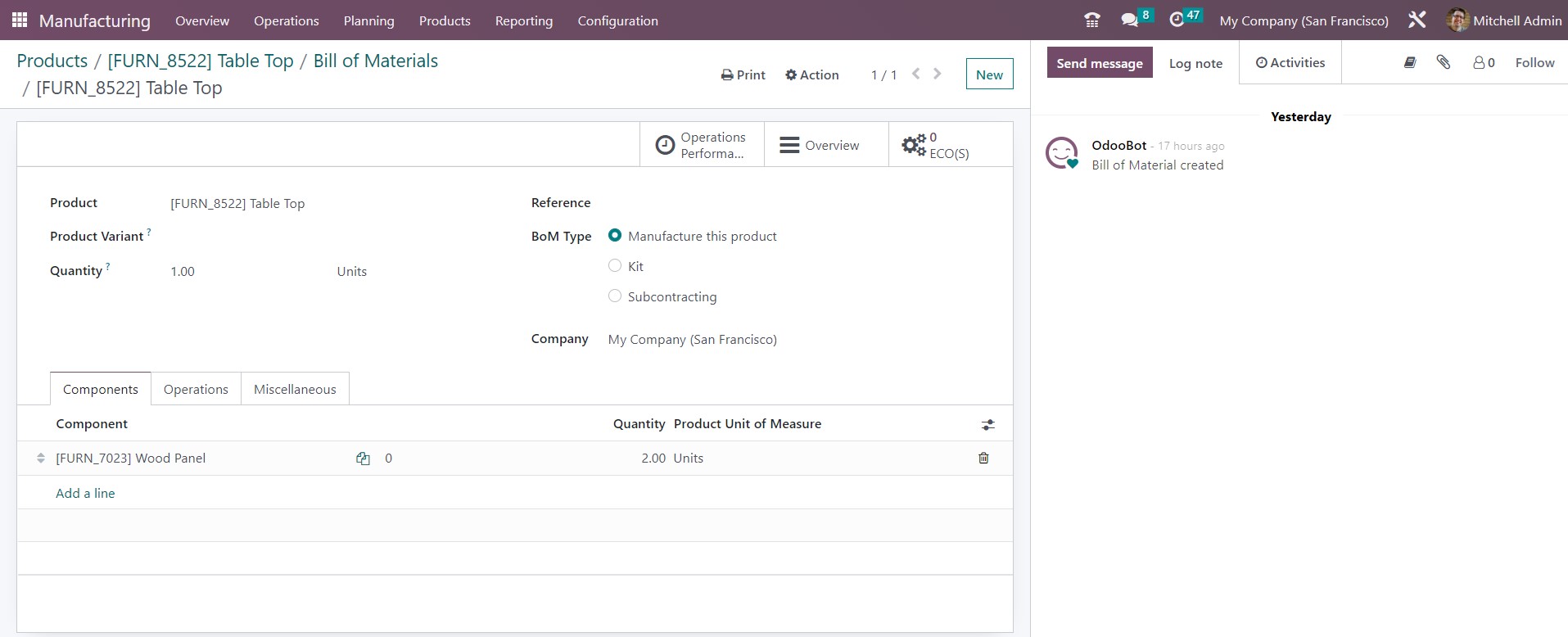

Step 2: Create the Bill of Materials (BoM) for the Table Top

You will have to create two Bills of Materials: one for the Table Top and one for the Large Meeting Table. Let’s start with the Table Top.

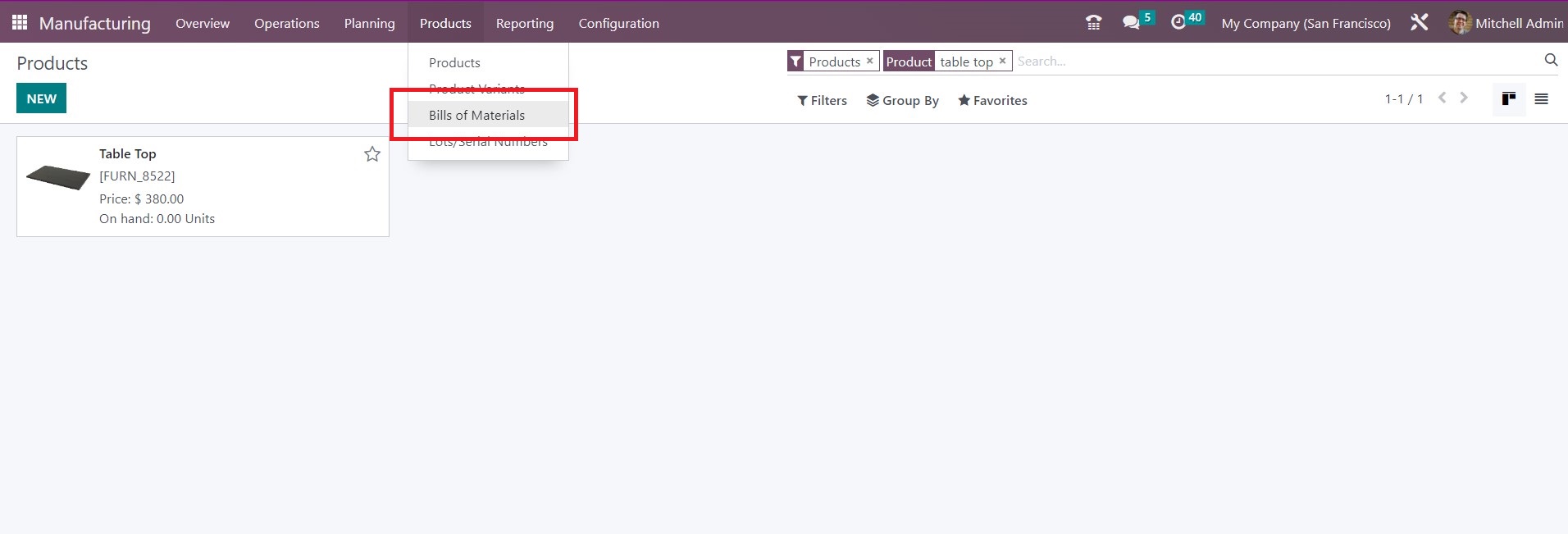

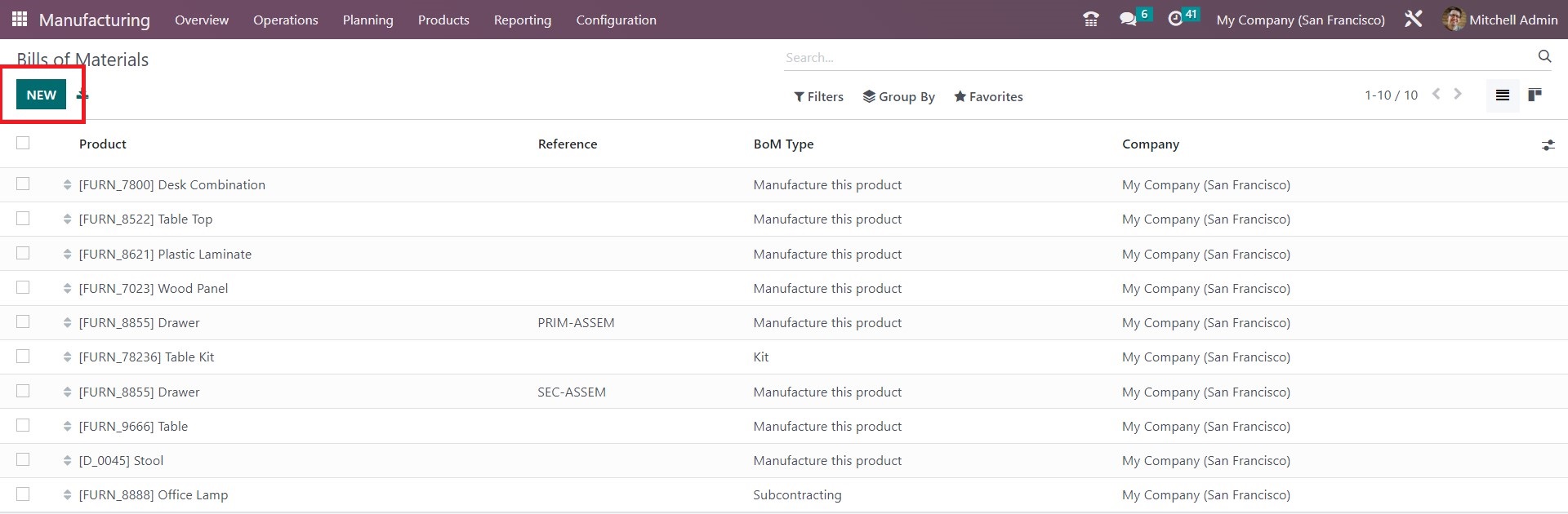

In Odoo, go to the "Manufacturing" module and select "Bill of Materials" from the main menu.

Click on the "New" button to start creating a new BoM.

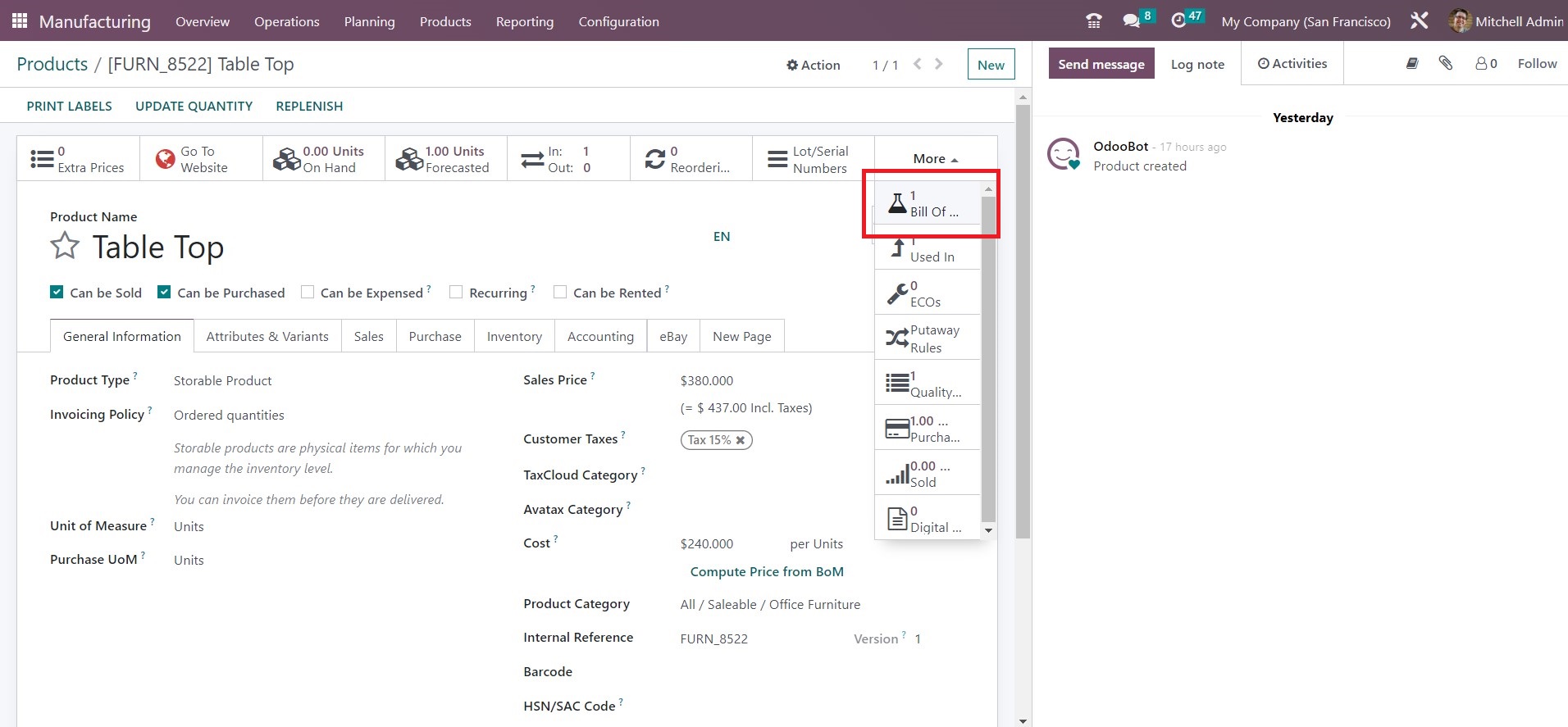

Or you can use a smart button in you Product card.

Step 3: Define the BoM Header Information

In the BoM creation form, you need to define the header information for your BoM. This includes specifying the product you are manufacturing, setting the BoM type as "Manufacture This Product," and providing a BoM code or name for easy reference.

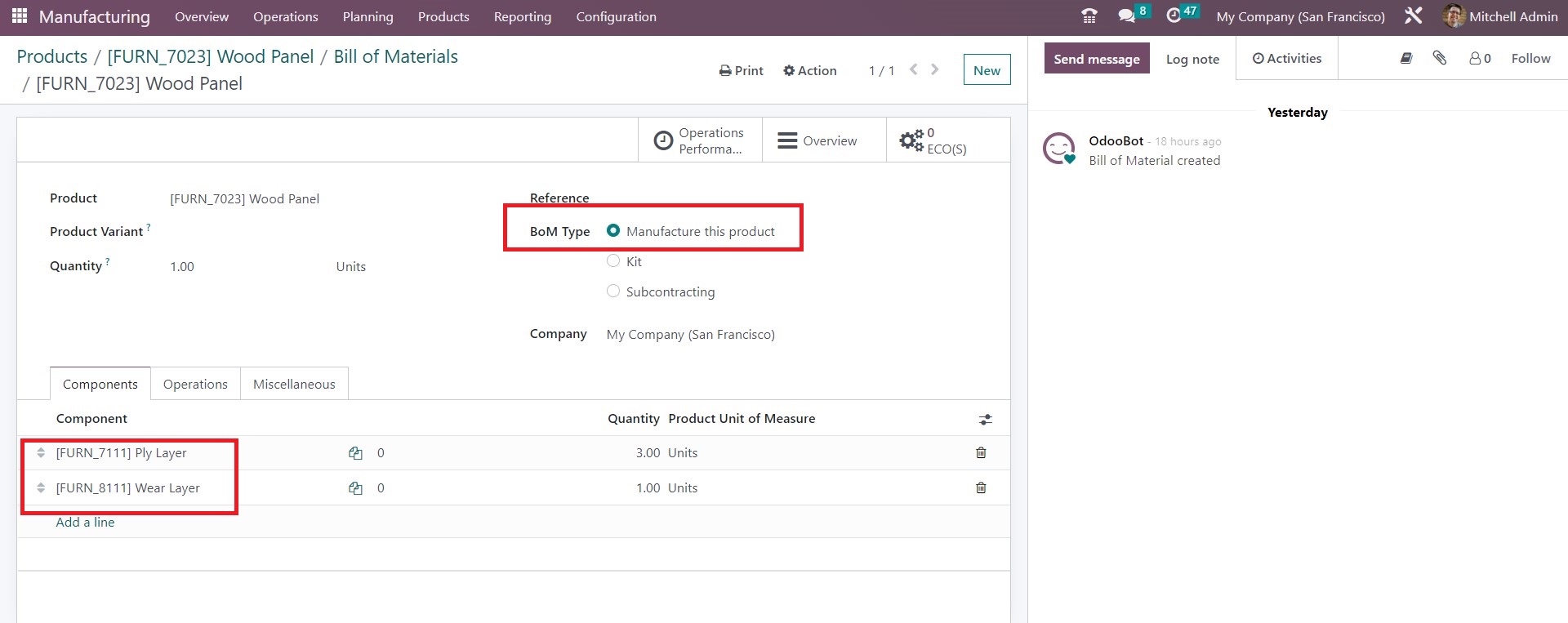

The component Wood Panel also should have its own BoM, so you should check if it is included and consists of 2 components, and the BoM type is to Manufacture this product.

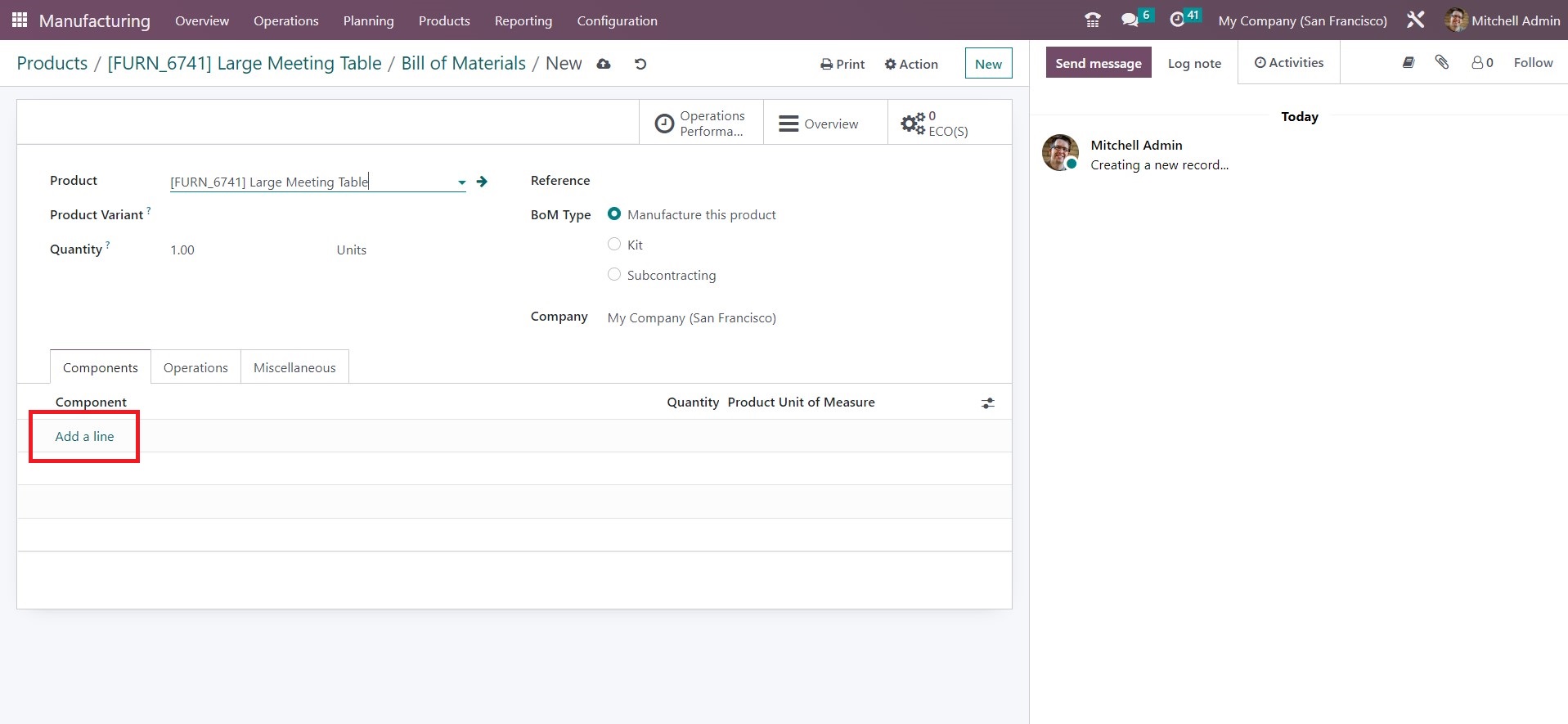

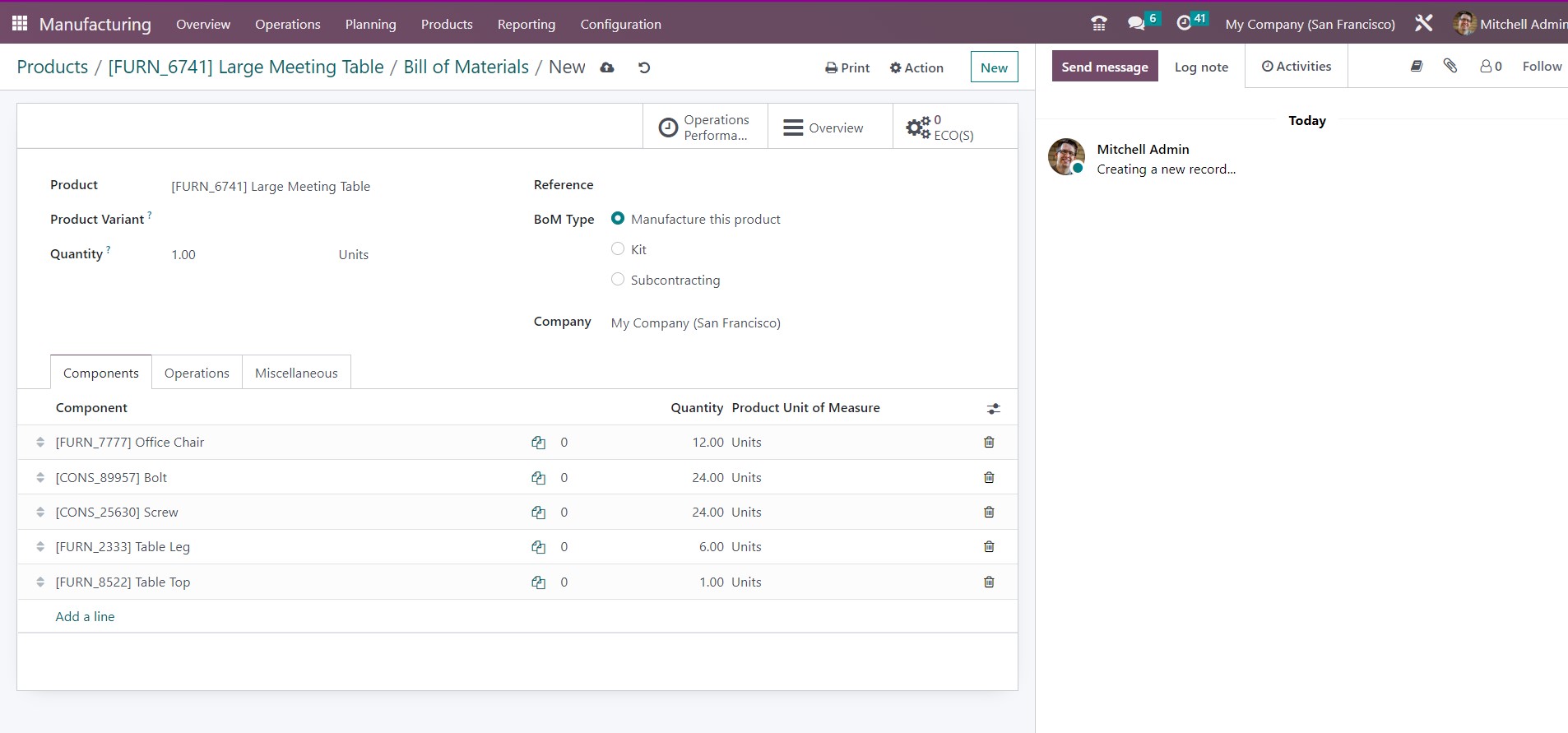

Step 4: Create BoM for the Large Meeting Table

Once you've created the Bill of Materials for the Table Top, it's time to repeat the process for the finished product. Start adding the components and sub-assemblies to your BoM. You can do this by clicking on the "Add a Line" button and selecting the product from the list of products that you previously defined in Step 1.

Specify the quantity of each component or sub-assembly required to produce one unit of the finished product.

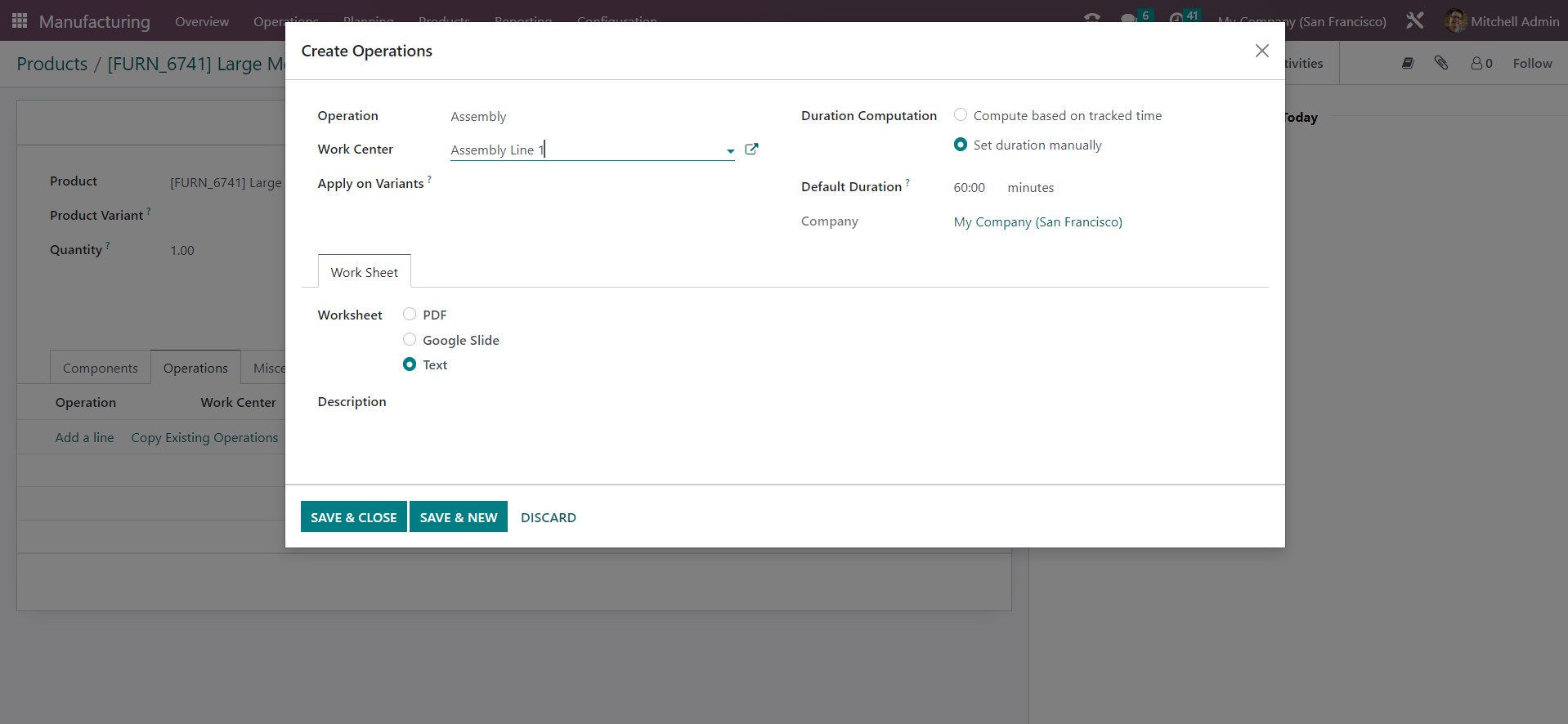

If applicable, you can also set the "Operation" field to define the production operation associated with each component or sub-assembly.

You can also add instructions to your employees in the Worksheet by uploading a PDF, Google Slide, or filling in Text.

Step 5: Use Your Multi-Level BoM in Your Manufacturing Process

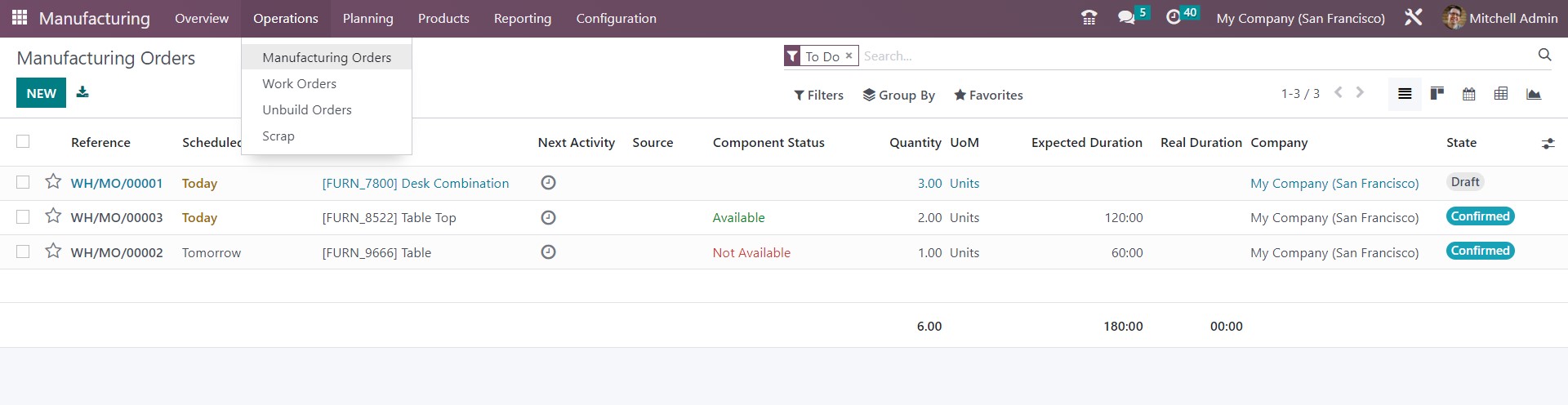

Now it’s time to create some Manufacturing Orders.

The Wood Panel should be produced the first.

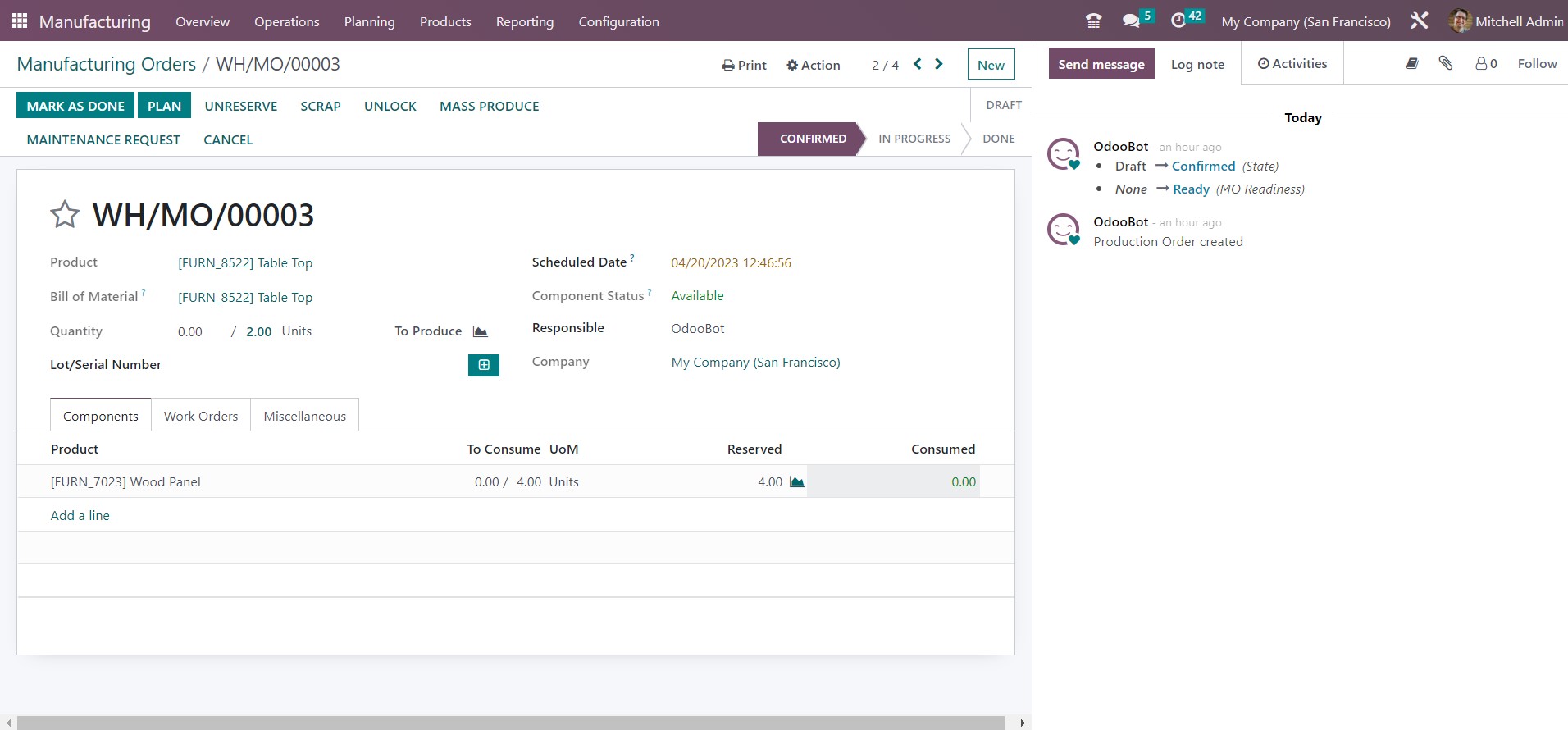

Then goes the Table Top.

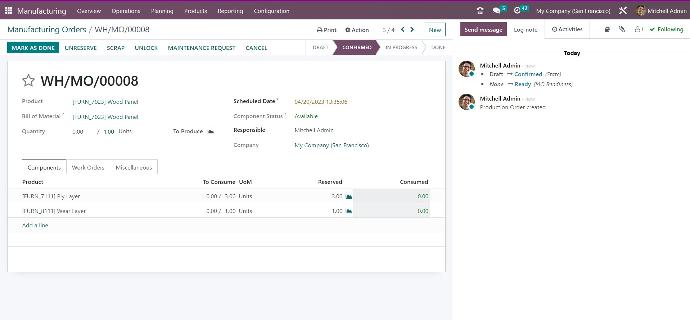

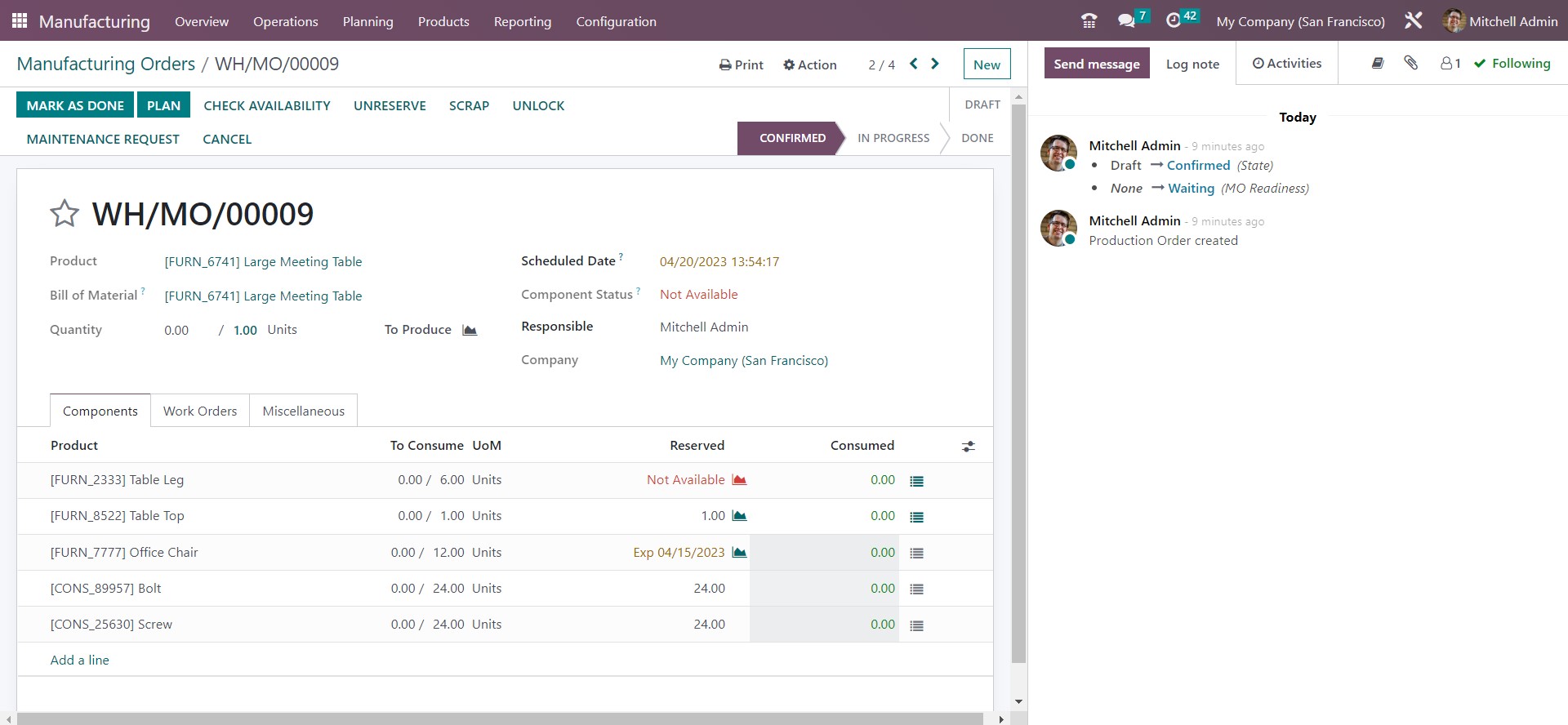

Finally, Large Meeting Table must be manufactured.

Here you can see that some components are not available yet. Once they are in stock, you can start manufacturing Large Meeting Table using this multi-level Bill of Materials.

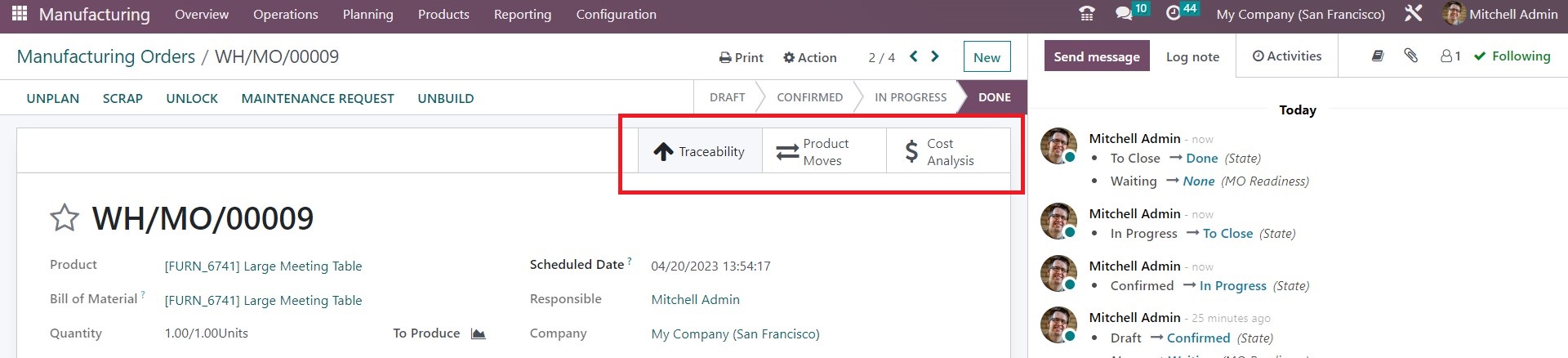

Step 6: Check Traceability, Product Moves and Cost Analysis

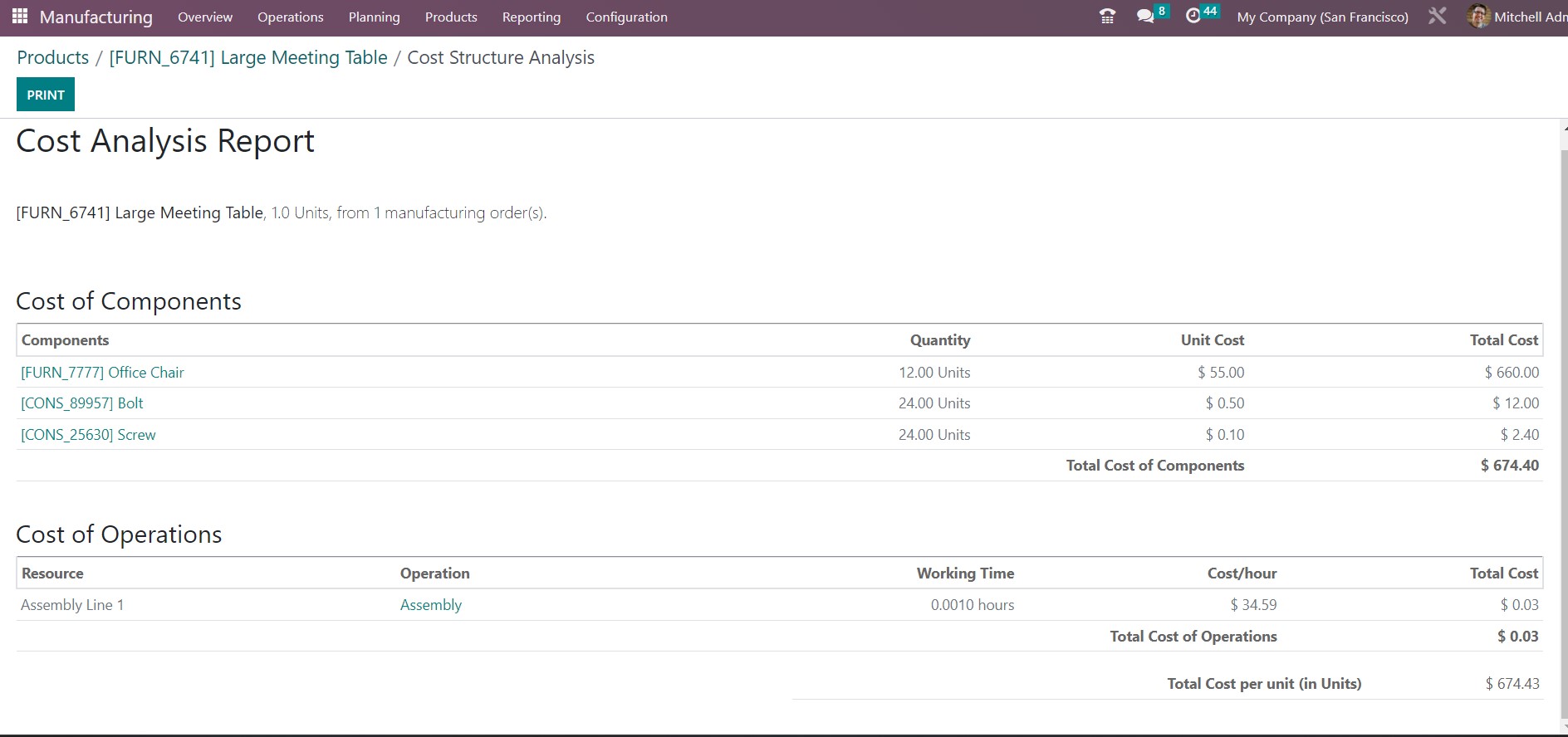

Once your product is manufactured, you can check traceability, product moves in the inventory, and cost analysis.

Here, for example, you can analyze cost of components and operations.

This is how you manage a multi-level BoM for a Large Meeting Table.

Conclusion

Mastering a multi-level Bill of Materials (BoM) in Odoo is essential for manufacturers who require a hierarchical structure of components and sub-assemblies in their manufacturing process. With the step-by-step guide provided in this article, you can create a multi-level BoM in Odoo, define the product structure, add components and sub-assemblies, set routing, and use it in your manufacturing process. By effectively managing your BoMs, you can streamline your manufacturing process, improve efficiency, and ensure accurate production planning and inventory management in Odoo ERP.